WATERJET CUTTING

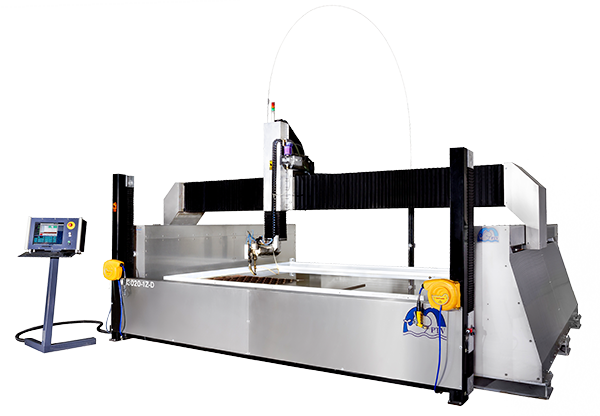

We provide custom-made waterjet cutting with the use of a rotating cutting head.

Work surface of CNC table

- Axis X………3000 mm

- Axis Y……….2000 mm

- Axis Z……….360 mm (500mm)

Principle of waterjet cutting

The point of separating the materials is in the abrasion of material by waterjet pressure. This process is in fact same as water erosion, but considerably accelerated and focused to one place.

Cutting is mostly controlled by CNC tables. Working waterjet pressure is in the range 2 000 – 4 150 Bar. The pressure comes from the special high pressure pump, which differs in input and flow rate of water. The beam is produced in the cutting head ending by cutting jet. While processing soft materials a pure water beam is used, whereas in other case it is necessary to use abrasive water jet. Natural olivine or garnet is a suitable abrasive additive - the choice depends on the hardness of the material to be cut.

The movement of the cutting head, and therefore the trajectory of the incision, is controlled by computer based on beforehand set up program.

Benefits

- The great advantage of waterjet is cutting without the material being exposed to heat, so called cold cut. There is no physical, chemical nor mechanical change of the material, and consequently it is easily workable.

- Minimal force impact of the beam on the material being cut, no microcracks are developed.

- Versatility – the beam divides most of the materials with wide range of cutting thickness

- Waterjet cutting is an environmentally friendly technology. During the processing no noxious fumes are produced. The water consumption is very little (depends on the pressure and the size of the jet used). All dirt is taken away from the wastewater by sedimentation. Only non-toxic abrasive additives, which can be recycled and repeatedly reemployed, are used. Used abrasive materials can be without problems disposed on waste dump.

- Minimal waste of material and therefore high usage of semi-products – the gap between products is approx. 3 mm

Materials suitable for waterjet cutting

- foam and plastic material, rubber

- plywood, balsa, floor covering

- fiberglass, composites, technical and advertising plastics

- electrical and thermal insulation materials

- marble, granite, sandstone, glass, tiles

- aluminum, titanium, copper, nickel alloys

- structural, alloy, tool and heat-treated steel, welded steel with extreme hardness